Impactful problem solving tends to tread the relatively unorthodox line between design and engineering. Successfully delivering change from idea to implementation in this field often requires the use of specialist engineering processes, techniques or skills. From working in industry as well as during my projects in academia, I’ve developed a valuable skillset for this.

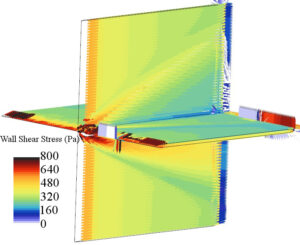

Computational Fluid Dynamics (CFD)

Running physical experiments in a wind tunnel is often too costly or infeasible for the problem at hand. CFD essentially provides a ‘virtual wind tunnel’ where design point performance can be tested at a fraction of the cost.

For example, renewable energy solutions involving wind turbines rely upon CFD studies. The positioning of turbines within a wind farm is such as to exploit the benefits from aerodynamic interactions of each other. These gains are impossible to quantify without CFD tools being utilised. Having honed my skills with STAR-CCM+ and ASYS Fluent tools, I look forward to opportunities where CFD analysis can support my future design decisions.

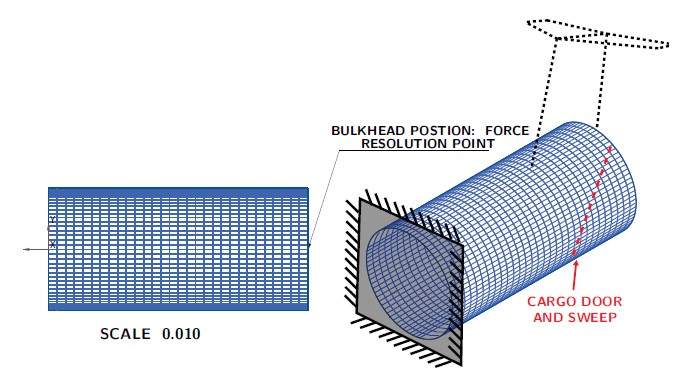

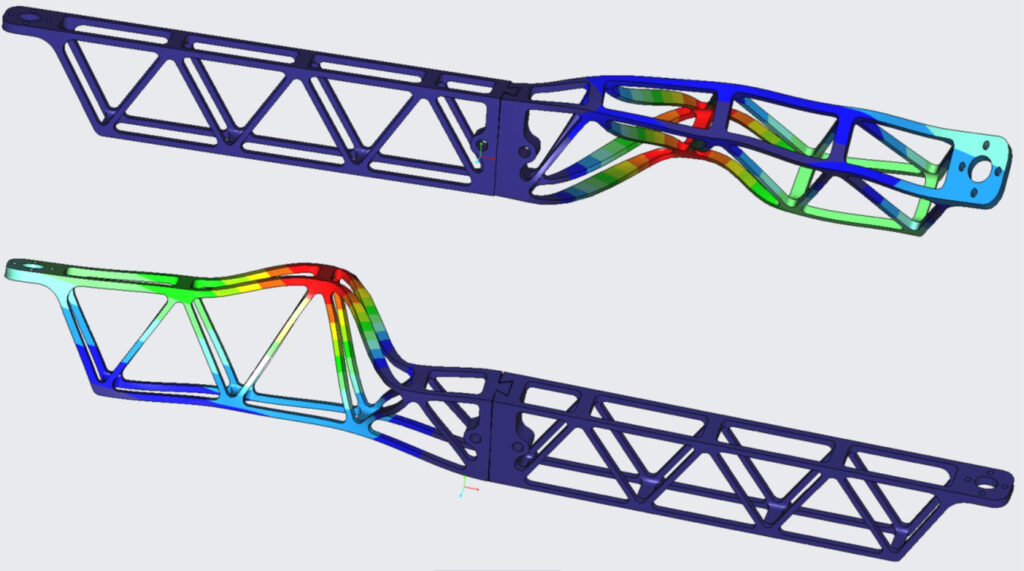

Finite Element Analysis (FEA)

I consider FEA an invaluable tool for a design engineer to gain confidence within the feasibility study phase. I’ve had the chance to hone skills with FEA when working on a multidisciplinary project to design a conceptual aircraft. Aircraft design is inherently interdisciplinary: many of the empirical sizing formulae are iterative and directly affect the sizing of related components. Thus, a constant feedback loop is present. FEA was a tool used to quantify the importance of changes and understand when the design becomes over-engineered. I’ve also found FEA valuable for analysing mode shapes of a duocopter structure during a group project. This validated the structural performance at the design point.

Matlab / Simulink

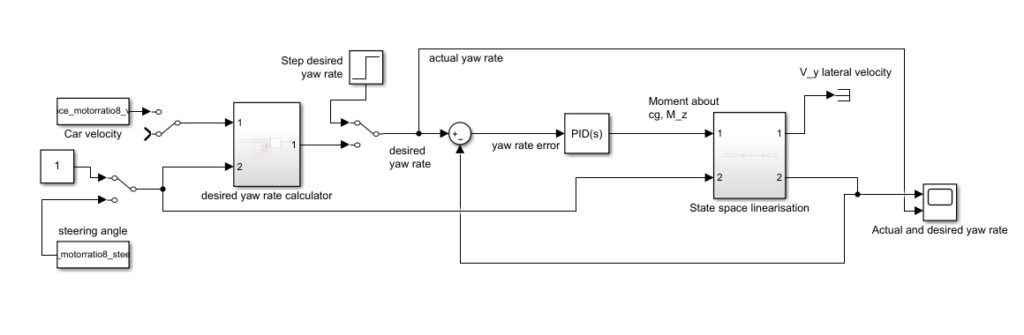

When designing for the human, and with the human-computer interaction, errors and feedback must be accounted for by design. This was exactly the case when working on a torque vectoring controller for a hybrid electric race car. The controller needed to be easily tuned on track. Similarly, the controller for the duocopter (above) required a capability to be tuned on- the-fly so it was imperative to have a easy to use and reliable controller. MATLAB codes and Simulink models were extremely effective in delivering these in both cases. I’ve found that MATLAB / Simulink is incredibly powerful for most engineering problems and is a skill I’ve always relied upon for projects in industry.